Municipal Drinking Water

Trusted Systems. Resourceful Thinking.

Tonka Water has been dedicated to meeting the potable water needs of public water systems across North America since 1956. As part of Kurita America, Tonka Water remains a trusted brand in municipal water treatment with over 2,700 installations.

Kurita America works to understand our customers’ specific needs and customize designs to deliver the optimal solution for each application. Our solutions draw from a broad portfolio of equipment and unit processes to treat a variety of source waters for regulated, emerging, or nuisance contaminants with products including solids contact clarifiers, media filters, ion exchange systems, aerators, membrane systems, controls automation, and aftermarket parts and consumables.

Kurita America’s commitment to quality and customer satisfaction permeates our operations from the initial sales process through delivery and throughout the equipment life cycle. Our ISO 9001:2015 certified quality management system reinforces our aim of continuous improvement. You can rely on our support and expertise to help ensure your water systems are operating reliably and sustainably.

Drinking Water Solutions

Our product portfolio encompasses the breadth of equipment necessary to treat any drinking water contaminant. Our products include the following:

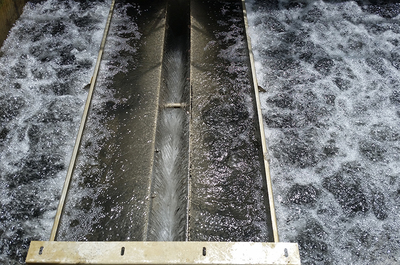

- Media filtration systems (pressure and gravity)

- Membrane filtration systems (NF/RO, UF)

- Solids contact clarifiers and settling systems

- Ion exchange and adsorption systems

- Aerators and packed stripping towers

- Packaged treatment systems (UTS™, Dualator® Series)

- Control panels, automation systems

- Process-specific system components

- Aftermarket parts and consumables

Our solutions incorporate the following processes to accommodate the removal of a variety of contaminants:

- Aeration and degasification

- Oxidation and precipitation

- Flocculation and co-precipitation

- HMO sorption (radium)

- Lime softening

- Sedimentation and clarification

- Media filtration

- Membrane filtration

- Ion exchange/adsorption

Kurita America offers a range of services, both remotely and in the field, to support our customers in maintaining system integrity and maximizing equipment life cycle. Our national equipment specialists (NESs), applications engineers, and other experienced water professionals are readily available to address your water treatment challenges.

Some of these services include the following:

- Process recommendation and preliminary equipment design planning

- Process feasibility assessment and pilot testing

- Equipment installation supervision and guidance

- Start-up and commissioning

- System inspection and performance assessment

- System and process troubleshooting

- General maintenance inspection

- Media condition assessment

Many public waters systems implement treatment equipment to meet regulations, address emerging contaminants of concern, or remove nuisance contaminants that negatively impact user experience. Our products are most commonly treating water for the following contaminants:

- Ammonia

- Arsenic

- Color

- Disinfection byproducts (TTHM, HAA5)

- Dissolved gases

- Hardness

- Hydrogen sulfide

- Fluoride

- Hexavalent chromium

- Iron

- Manganese

- Nitrate

- Per- and polyfluoroalkyl substances (PFAS)

- Radium

- Radon

- Total and dissolved organic carbon (TOC/DOC)

- Total dissolved solids (TDS)

- Total suspended solids (TSS)

- Turbidity and associated pathogens

- Uranium

- Volatile organic compounds (VOC)

Trending Topics

Per- and polyfluoroalkyl substances (PFAS) are prevalent in the environment due to their widespread use in various industrial and consumer products. State and pending federal regulations in the United States require the removal of several types of PFAS, including perfluorooctanoic acid (PFOA) and perfluorooctanesulfonic acid (PFOS), from drinking water sources. As a result, many public water systems must add previously unnecessary treatment equipment.

When addressing PFAS, it is important to develop a comprehensive treatment strategy that considers the total water quality. An integrated approach with pre-treatment will often deliver better water while reducing life cycle costs. Contact us to discuss possible treatment options for your specific PFAS application.

The Build America, Buy America (BABA) Act became law in November of 2021 with the enacting of the Infrastructure Investment and Jobs Act (IIJA). It requires that all products with few exceptions incorporated into federally funded infrastructure projects be produced in the United States with separate definitions for iron and steel products, manufactured products, and construction materials.

Kurita America manufactures all equipment systems in the United States, and our existing supply chain supports the 55% domestic component content required for BABA compliance. Contact us to discuss your project and understand how to navigate these new requirements.

Read this article as featured in the Journal of the New England Water Works Association to learn more about BABA and the impact on service providers to the water industry.